The coal samples were taken from the Illinois, Northern Appalachian, Central Appalachian, Rocky Mountain Coal Basins, and the Pennsylvania Anthracite region. The samples showed REEs at concentrations greater than 300 parts per million (ppm).

In a news release, NETL said: “Concentrations of rare earths at 300ppm are integral to the commercial viability of extracting REEs from coal and coal by-products, making NETL’s finding particularly significant in the effort to develop economical domestic supplies of these elements.”

The discovery was made in partnership with West Virginia University (WVU), the University of Kentucky (UK), Tetra Tech, and the XLight Corporation. For their part, WVU explored acid mine drainage from bituminous coal mines in the Northern and Central Appalachian Coal Basins, while Tetra Tech looked at bituminous, subbituminous, and anthracite coal from the same basins.

Meanwhile, UK analyzed western Kentucky bituminous coal in the Illinois Coal Basin, and XLight Corporation investigated coal-related materials in the Eastern Pennsylvania Anthracite Region.

US Energy Secretary Rick Perry said: “Rare Earth Elements are vital to the development and manufacturing of high-tech devices such as computers, cell phones, and our national defense systems. The current difficulties and high expenses associated with REE extraction have left the U.S. dependent on foreign REE imports.”

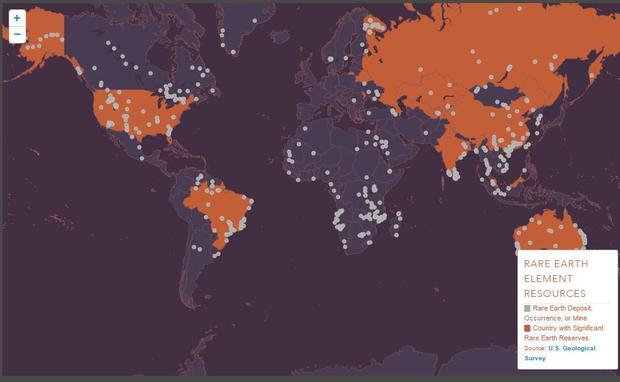

U.S. imports of rare earth elements

According to The Hill in June this year, the U.S. Geological Survey reported that last year the U.S. imported $120 million worth of rare earth compounds, the vast majority from China. This only understates our dependence on rare earths because we also import billions of dollars worth of electronic products that contain rare earths.

And for years, China has had a monopoly on trade in REEs, accounting for nearly 90 percent of the world’s production, in effect, regulating prices to the advantage of its own Chinese customers with export restraints on rare earths imposed in 2009, causing anger and consternation worldwide.

The rare earth elements are a group of 17 little-known elements, most of them with unpronounceable names like neodymium or ytterbium. However, these elements are very vital to the manufacture of electronic components like smartphone displays, sensors, and electric motors. They are also vital for defense applications.

Initiatives started in the U.S.

This dependence on REEs from abroad is one reason the discovery of these elements in U.S. coal basins is so important. The DOE says this will encourage technology developers to recover REEs from these basins by helping them find high-quality feedstocks—the raw materials needed for REE recovery processes.

A separate research initiative is focusing on DOE cost-shared research projects to design, develop, and test technology to actually recover REEs from coal-related materials in a variety of American coal basins. These projects began in October 2017.

They will be using materials from the high-REE containing coal basins as feedstocks, such as acid mine drainage from bituminous mines in the Northern and Central Appalachian Coal Basins. DOE says they are well on the way to final design and the construction of bench-scale test facilities beginning in January 2018.

Meanwhile, the University of Kentucky began pilot-scale design and construction in October 2017 for systems using West Kentucky bituminous coal preparation plant refuse from the Illinois Coal Basin. A second pilot-scale facility is being designed and constructed by Physical Sciences Inc.

Additional analytical results for REE-bearing coal-related material at the state and/or county level can be found at NETL’s Rare Earth Elements Energy Data eXchange website.